PRODUCT PARAMETERS

| Product Name | Pipe cap |

| Size | 1/2"-60" seamless, 60"-110" welded |

| Standard | ANSI B16.9, EN10253-4, DIN2617, GOST17379, JIS B2313, MSS SP 75, etc. |

| Wall thickness | SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS ,customized and etc. |

| End | Bevel end/BE/buttweld |

| Surface | pickled, sand rolling, polished, mirror polishing and etc. |

| Material | Stainless steel: A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400, Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

STEEL PIPE CAP

Steel Pipe Cap is also called Steel Plug, it usually welded to the pipe end or mounted on the external thread of the pipe end to cover the pipe fittings. To close the pipeline so the function is the same as the pipe plug.

CAP TYPE

Ranges from connection types, there are: 1.Butt weld cap 2.Socket weld cap

BW Steel Cap

BW steel pipe cap is the butt weld type of fittings, connecting methods is to use butt welding. So BW cap ends in beveled or plain.

BW cap dimensions and weight:

| Normial pipe size | OutsideDiameterat Bevel(mm) | LengthE(mm) | Limiting WallThicknessfor Length,E | LengthE1(mm) | Weight(kg) | |||||

| SCH10S | SCH20 | STD | SCH40 | XS | SCH80 | |||||

| 1/2 | 21.3 | 25 | 4.57 | 25 | 0.04 | 0.03 | 0.03 | 0.05 | 0.05 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 | 0.06 | 0.06 | 0.06 | 0.10 | 0.10 | |

| 1 | 33.4 | 38 | 4.57 | 38 | 0.09 | 0.10 | 0.10 | 0.013 | 0.13 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 | 0.13 | 0.14 | 0.14 | 0.20 | 0.20 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 | 0.14 | 0.20 | 0.20 | 0.23 | 0.23 | |

| 2 | 60.3 | 38 | 5.59 | 44 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 | 0.30 | 0.20 | 0.50 | 0.50 | 0.50 | |

| 3 | 88.9 | 51 | 7.62 | 64 | 0.45 | 0.70 | 0.70 | 0.90 | 0.90 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 | 0.60 | 1.40 | 1.40 | 1.70 | 1.70 | |

| 4 | 114.3 | 64 | 8.64 | 76 | 0.65 | 1.6 | 1.6 | 2.0 | 2.0 | |

| 5 | 141.3 | 76 | 9.65 | 89 | 1.05 | 2.3 | 2.3 | 3.0 | 3.0 | |

| 6 | 168.3 | 89 | 10.92 | 102 | 1.4 | 3.6 | 3.6 | 4.0 | 4.0 | |

| 8 | 219.1 | 102 | 12.70 | 127 | 2.50 | 4.50 | 5.50 | 5.50 | 8.40 | 8.40 |

| 10 | 273 | 127 | 12.70 | 152 | 4.90 | 7 | 10 | 10 | 13.60 | 16.20 |

| 12 | 323.8 | 152 | 12.70 | 178 | 7 | 9 | 15 | 19 | 22 | 26.90 |

| 14 | 355.6 | 165 | 12.70 | 191 | 8.50 | 15.50 | 17 | 23 | 27 | 34.70 |

| 16 | 406.4 | 178 | 12.70 | 203 | 14.50 | 20 | 23 | 30 | 30 | 43.50 |

| 18 | 457 | 203 | 12.70 | 229 | 18 | 25 | 29 | 39 | 32 | 72.50 |

| 20 | 508 | 229 | 12.70 | 254 | 27.50 | 36 | 36 | 67 | 49 | 98.50 |

| 22 | 559 | 254 | 12.70 | 254 | 42 | 42 | 51 | 120 | ||

| 24 | 610 | 267 | 12.70 | 305 | 35 | 52 | 52 | 93 | 60 | 150 |

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI

4. PT, UT,X-ray test.

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE

7. ASTM A262 practice E

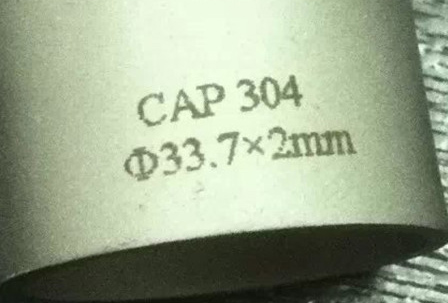

MARKING

Various marking work can be on your request. We accept mark your LOGO.

FAQ

1. What is a stainless steel welded pipe end pressure vessel cap?

Stainless steel welded pipe end pressure vessel cover is a component used to seal the ends of pressure vessel pipes connected by welding. It is made of stainless steel, ensuring durability and corrosion resistance.

2. What are the advantages of using stainless steel welded pipe end pressure vessel covers?

The use of stainless steel welded pipe end pressure vessel covers has the advantages of high strength, high pressure resistance, high temperature resistance, and corrosion resistance. It ensures a secure seal and helps maintain the integrity of the pressure vessel.

3. How to install the stainless steel welded pipe end pressure vessel cover?

To install a stainless steel welded pipe end pressure vessel cap, use appropriate welding techniques to weld the cap to the end of the pressure vessel pipe. It is critical to ensure proper alignment and secure welding for a reliable seal.

4. Are stainless steel welded pipe end pressure vessel covers available in different sizes?

Yes, stainless steel welded pipe end pressure vessel covers are available in different sizes to accommodate various pipe diameters. Choosing the right size to ensure a proper fit and seal is critical.

5. Can stainless steel welded pipe end pressure vessel covers be used in high-pressure applications?

Yes, stainless steel welded pipe end pressure vessel covers are designed to withstand high pressure applications. They are constructed to withstand the forces exerted by the pressure within the container and maintain a tight seal.

6. Is the stainless steel welded pipe end pressure vessel cover corrosion-resistant?

Yes, stainless steel welded pipe end pressure vessel covers are highly corrosion resistant. Stainless steel is known for its corrosion-resistant properties, making it suitable for a variety of industrial applications.

7. Can stainless steel welded pipe end pressure vessel covers be used with different types of pressure vessels?

Yes, stainless steel welded pipe end pressure vessel covers are versatile and can be used with various types of pressure vessels, including those used in the oil and gas, chemical and pharmaceutical industries.

8. What is the service life of the stainless steel welded pipe end pressure vessel cover?

The service life of stainless steel welded pipe end pressure vessel caps depends on factors such as the cap's usage conditions, maintenance and quality. With proper maintenance and regular inspections, they can last for many years.

9. Are there any specific safety precautions when using stainless steel welded pipe end pressure vessel covers?

When using stainless steel welded pipe end pressure vessel covers, safety precautions should be followed, such as using proper welding techniques to ensure a strong and leak-free seal. To ensure safety, you also need to check regularly for signs of wear or damage.

10. Can the stainless steel welded pipe end pressure vessel cover be customized?

Yes, depending on the manufacturer, stainless steel welded pipe end pressure vessel covers can be customized to meet specific requirements. Customization options may include different materials, sizes and designs to suit individual applications.

-

ANSI B16.9 butt weld Pipe Fitting carbon steel ...

-

ASME B16.9 A105 A234WPB Carbon steel butt weld ...

-

8 Inch stainless steel pipe cap pipe end cap he...

-

LStainless Steel 304L Butt-Weld Pipe Fitting Se...

-

White Steel Pipe Reducer SCH 40 Stainless Steel...

-

ANSI B16.9 Carbon Steel 45 Degree Welding Bend