PRODUCT DESCRIPTION

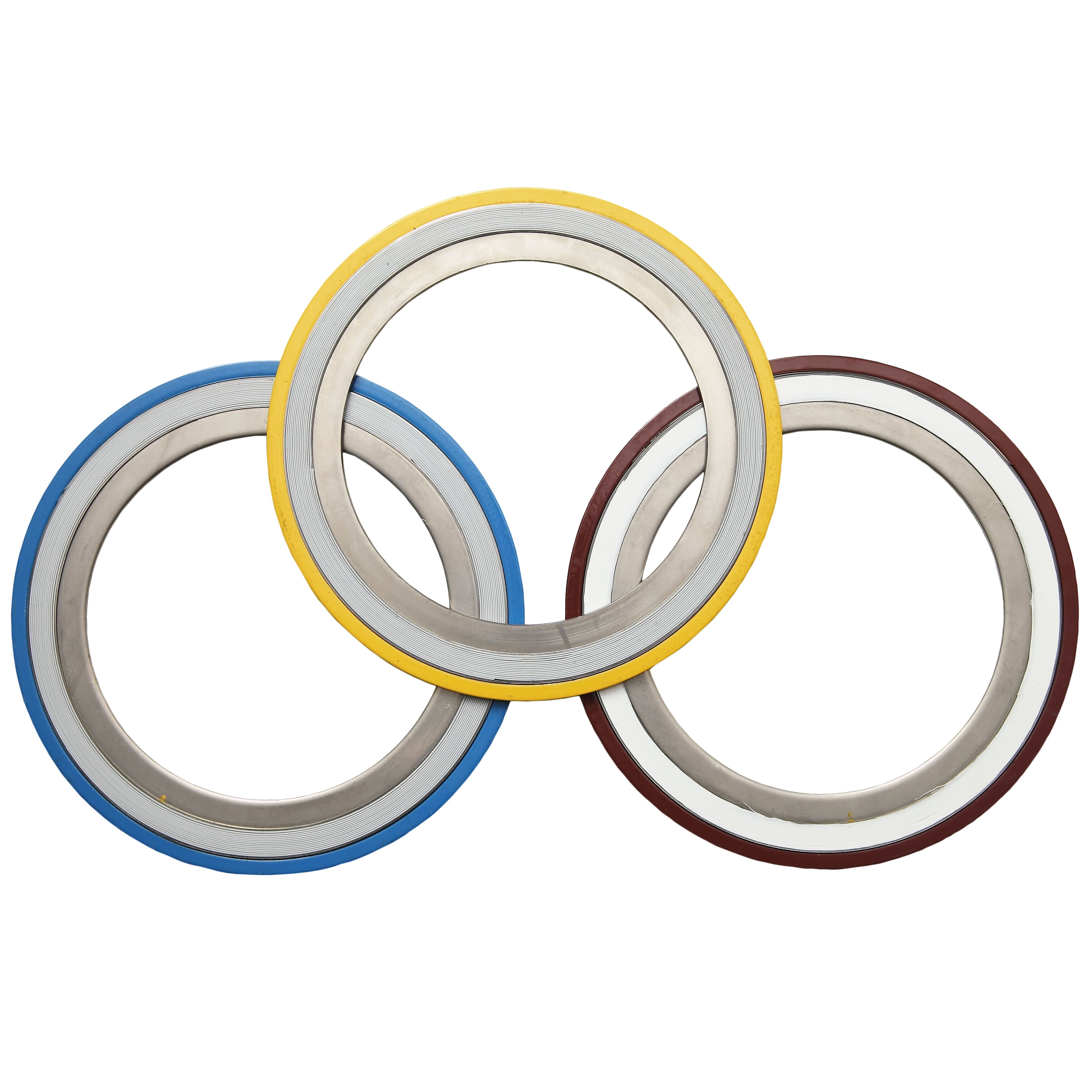

Flange gaskets

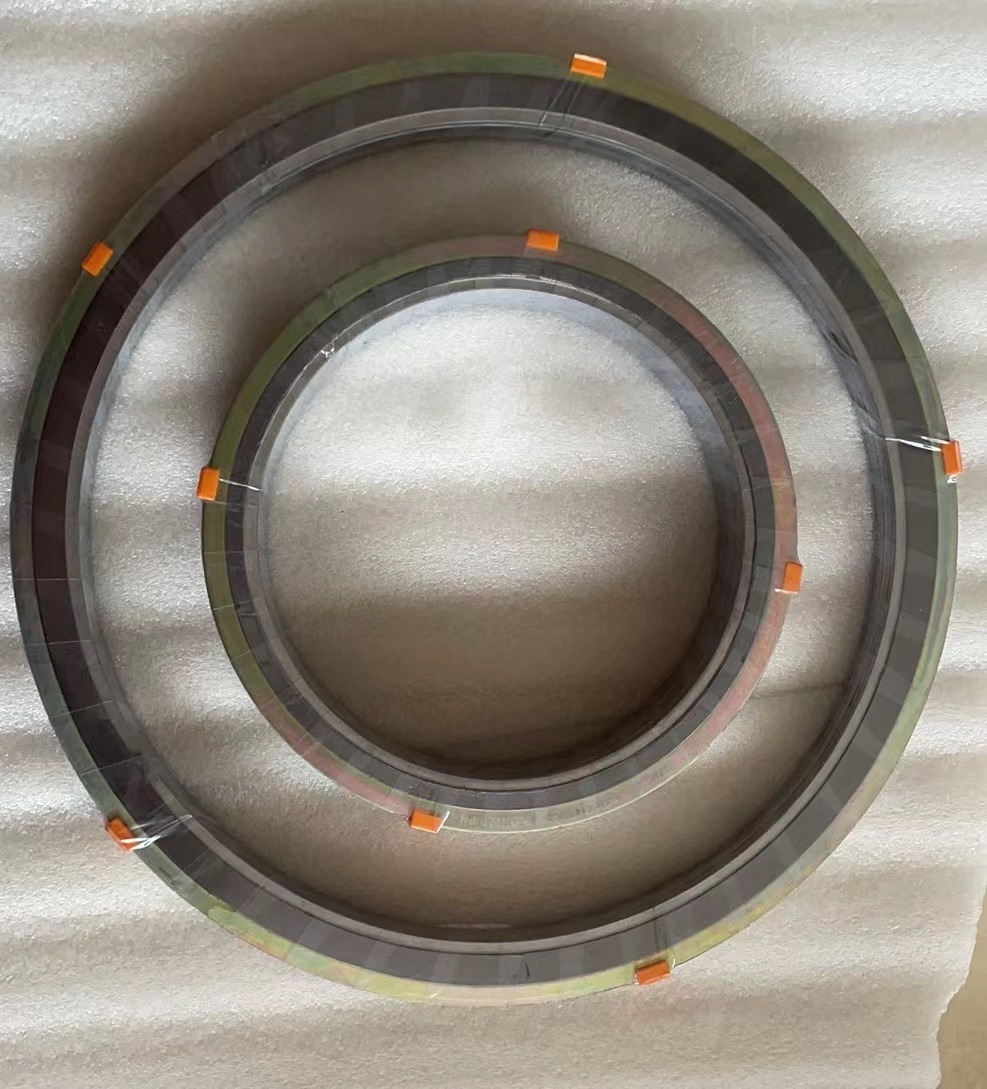

Flange gaskets are divided into rubber gaskets, graphite gaskets, and metal spiral gaskets (basic type). They use standard and

materials are overlapped and spirally wound, and the metal band is fixed by spot welding at the beginning and the end. Its

function is to play a sealing role in the middle of the two flanges.

Performance

Performance: high temperature, high pressure, corrosion resistance, good compression rate and rebound rate. Application: Sealing

parts of pipes, valves, pumps, manholes, pressure vessels and heat exchange equipment at the joints of petroleum, chemical,electric power, metallurgy, shipbuilding, papermaking, medicine, etc. are ideal static sealing materials.

and high pressure steam, oil, oil and gas, solvent, hot coal body oil, etc.

PRODUCT PARAMETERS

|

Filler Materials

|

Asbestos

|

Flexible graphite(FG)

|

Polytetrafluoroethylene(PTFE)

|

|

Steel belt

|

SUS 304

|

SUS 316

|

SUS 316L

|

|

Inner Ring

|

Carbon Steel

|

SUS 304

|

SUS 316

|

|

Outer Ring Materials

|

Carbon Steel

|

SUS 304

|

SUS 316

|

|

Temperature (°C)

|

-150~450

|

-200~550

|

240~260

|

|

Maximum operating pressure (kg/cm2)

|

100

|

250

|

100

|

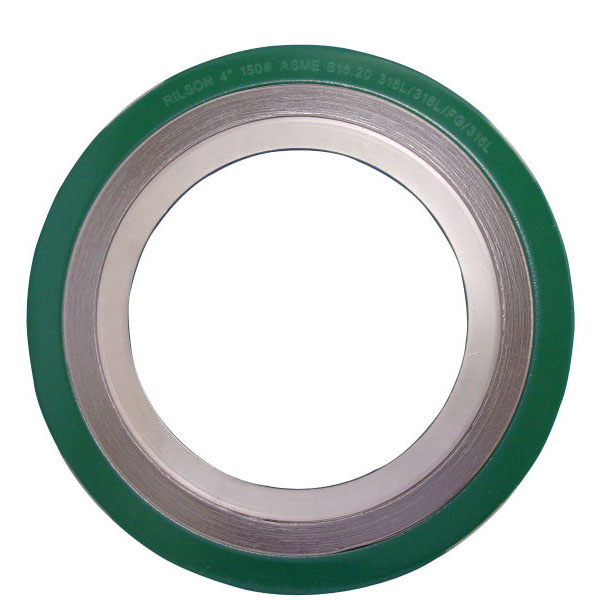

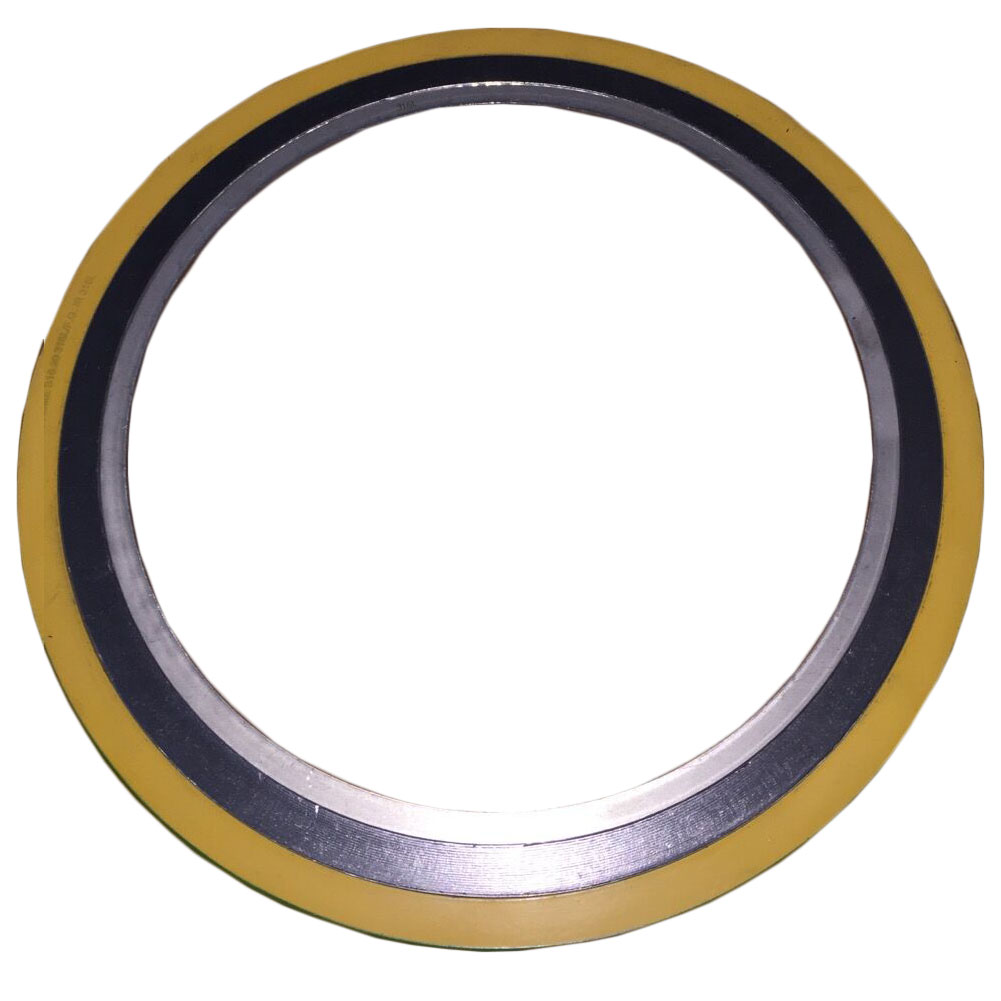

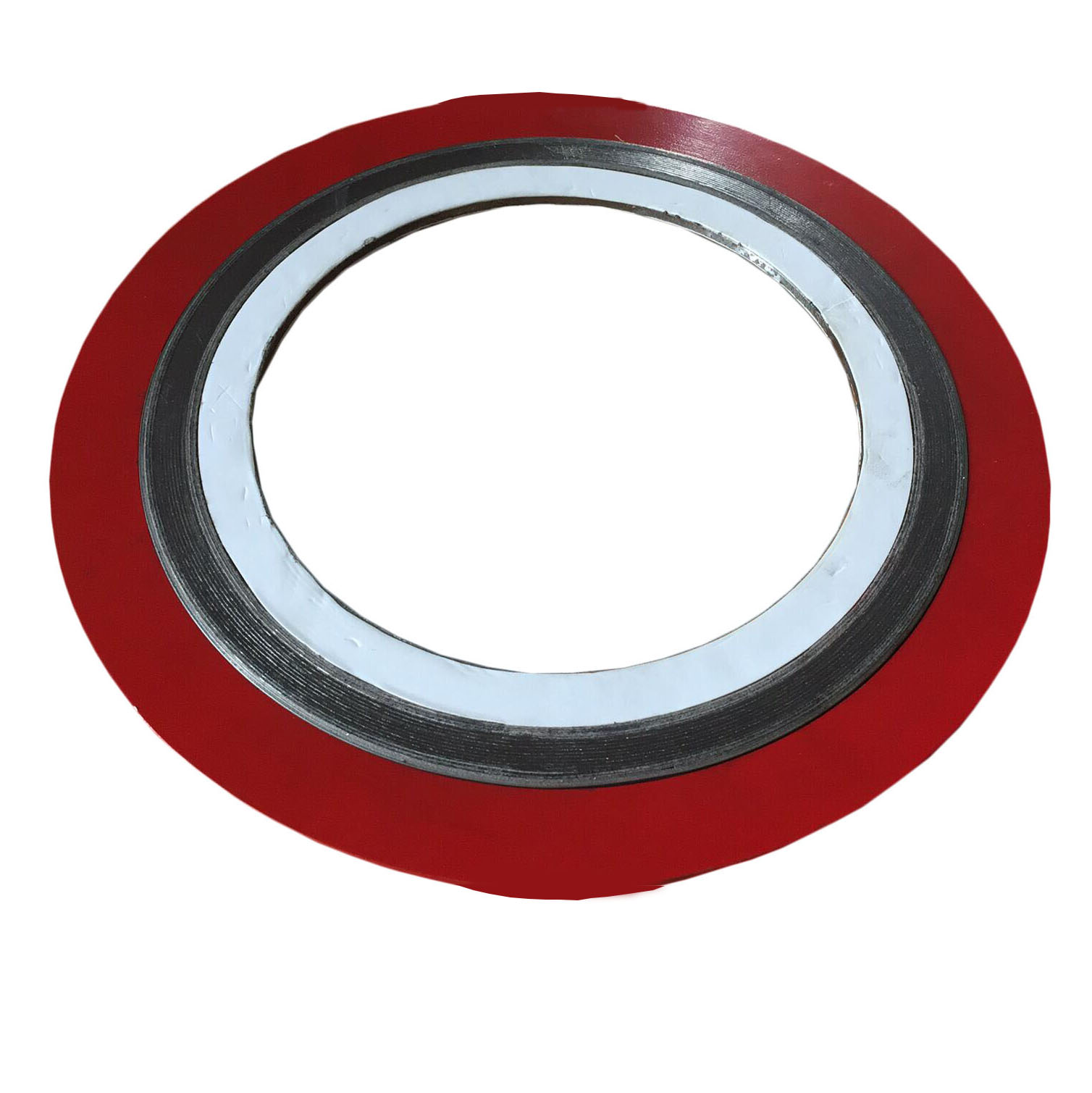

DETAILED PHOTOS

1. ASME B16.20 as per custoomers drawing

2. 150#,300#,600#,900#1500#,2500#,etc

3. Without lamination and cracks.

4. For flange on the pipeline or other

PACKAGING& SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

ABOUT US

We Have More Than 20+ Years Practical Experience in Agency

More 20 years production experience. The products we can offer steel pipe, bw pipe fittings, forged fittings, forged flanges, industrial valves. Bolts& Nuts, and gaskets. Materials can be carbon steel, stainless steel, Cr-Mo alloy steel, inconel, incoloy alloy, low temperature carbon steel, and so on. We would like offer whole package of your projects, to help you save cost and more easy to import.

FAQ

1. What is stainless steel graphite filler?

Stainless Steel Graphite Packing is a packing or sealing material used to prevent leaks in applications involving high temperatures and pressure. It is composed of braided stainless steel wire and impregnated graphite for excellent heat resistance and chemical compatibility.

2. Where are stainless steel graphite fillers commonly used?

Stainless steel graphite fillers are commonly used in various industries including chemical processing, petrochemical, oil and gas, power generation, pulp and paper, and more. It is suitable for applications involving fluids such as acids, solvents, steam and other corrosive media.

3. What are the advantages of stainless steel graphite filler?

Some of the advantages of stainless steel graphite packing include high temperature resistance, excellent chemical resistance, low coefficient of friction, good thermal conductivity and superior sealing properties. It can also handle high rpm and shaft speeds without compromising its effectiveness.

4. How to install stainless steel graphite packing?

To install stainless steel graphite packing, remove old packing and clean the stuffing box thoroughly. Cut the new packing material to the desired length and insert it into the stuffing box according to the manufacturer's instructions. Use the packing gland to evenly compress the packing and secure the packing gland to prevent leakage.

5. What is a spiral wound gasket?

A spiral wound gasket is a semi-metallic gasket consisting of alternating layers of metal and filler material (usually graphite or PTFE). These gaskets are designed to provide a tight and reliable sealing solution for flange connections subjected to high temperatures, pressures and various media.

6. Where are spiral wound gaskets commonly used?

Spiral wound gaskets are commonly used in industries such as chemical processing, oil and gas, refineries, power generation and pipelines. They are suitable for applications involving steam, hydrocarbons, acids and other corrosive fluids.

7. What are the advantages of spiral wound gaskets?

Some of the advantages of spiral wound gaskets include resistance to high temperatures and pressures, excellent elasticity, excellent sealing capabilities, adaptability to flange irregularities, and excellent chemical compatibility. They can also withstand thermal cycling and maintain seal integrity.

8. How to choose a suitable spiral wound gasket?

To select the appropriate spiral wound gasket, consider factors such as operating temperature and pressure, fluid type, flange surface finish, flange size, and the presence of any corrosive media. Consulting with the gasket supplier or manufacturer can help determine the best gasket for the application.

9. How to install spiral wound gasket?

To install a spiral wound gasket, make sure the flange face is clean and free of any debris or old gasket material. Center the washer on the flange and align the bolt holes. Apply even pressure when tightening the bolts to ensure even pressure on the gasket. Follow the recommended tightening sequence and torque values provided by the gasket manufacturer.

10. Can spiral wound gaskets be reused?

Although spiral wound gaskets can be reused in some cases, it is generally recommended to replace them with new gaskets to ensure optimal sealing performance. Reusing gaskets can result in performance degradation, loss of compression, and potential leaks. Regular inspection and maintenance practices should be followed to promptly identify and replace worn gaskets.