PRODUCT PARAMETERS

|

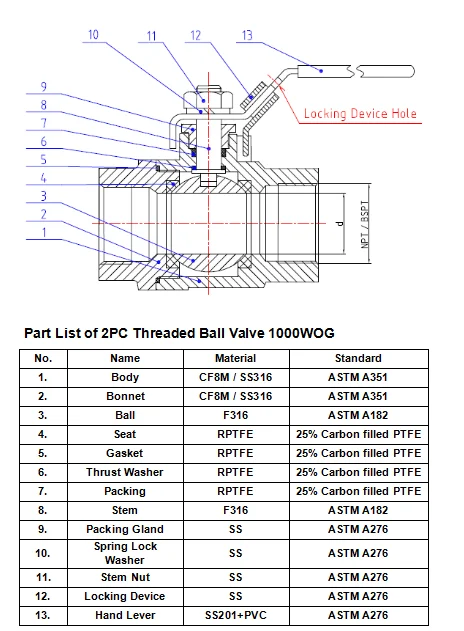

No.

|

Name

|

Material

|

Standard

|

|

1.

|

Body

|

CF8M/SS316

|

ASTM A351

|

|

2.

|

Bonnet

|

CF8M/SS316

|

ASTM A351

|

|

3.

|

Ball

|

F316

|

ASTM A182

|

|

4.

|

Seat

|

RPTFE

|

25% Carbon filled PTFE

|

|

5.

|

Gasket

|

RPTFE

|

25% Carbon filled PTFE

|

|

6.

|

Thrust Washer

|

RPTFE

|

25% Carbon filled PTFE

|

|

7.

|

Packing

|

RPTFE

|

25% Carbon filled PTFE

|

|

8.

|

Stem

|

F316

|

ASTM A182

|

|

9.

|

Packing Gland

|

SS

|

ASTM A276

|

|

10.

|

Spring Lock Washer

|

SS

|

ASTM A276

|

|

11.

|

Stem Nut

|

SS

|

ASTM A276

|

|

12.

|

Locking Device

|

SS

|

ASTM A276

|

|

13.

|

Hand Lever

|

SS201+PVC

|

ASTM A276

|

PRODUCT CHARACTERISTICS

Manual ball valve is a relatively new type of ball valve category, it has its own structure has some unique advantages, such as no friction switch, seal is not easy to wear, small opening and closing torque. This reduces the size of the configured actuator. With a multi-turn electric actuator, the medium can be adjusted and tightly cut off. It is widely used in petroleum, chemical industry, urban water supply and drainage and other conditions requiring strict cut-off.

The manual ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. Ball valve is a new type of valve widely used in recent years, it has the following advantages:

1. The fluid resistance is small, and its resistance coefficient is equal to that of the pipe segment of the same length.

2. Simple structure, small size, light weight.

3. Tight and reliable, the sealing surface material of the ball valve is widely used in plastic, good sealing, and has been widely used in the vacuum system.

4. Easy to operate, open and close quickly, from full open to full close as long as the rotation of 90 degrees, easy to remote control.

5. Easy maintenance, ball valve structure is simple, the sealing ring is generally active, disassembly and replacement are more convenient.

6. When fully open or fully closed, the sealing surface of the ball and the seat is isolated from the medium, and the medium will not cause erosion of the valve sealing surface when it passes through.

7. Wide range of application, small diameter to a few millimeters, large to a few meters, from high vacuum to high pressure can be applied. When the ball is rotated 90 degrees, the inlet and outlet should all be spherical, thus cutting off the flow.

STRUCTURAL CHARACTERISTICS

1. Frictionless opening and closing. This function completely solves the problem that the sealing of traditional valves is affected by the friction between the sealing surfaces.

2, top type structure. The valve installed on the pipeline can be directly checked and repaired online, which can effectively reduce the device parking and reduce the cost.

3, single seat design. The problem that the medium in the valve cavity is affected by abnormal pressure increase is eliminated.

4, low torque design. The valve stem with special structure design can be easily opened and closed with a small hand handle.

5, wedge sealing structure. The valve is sealed by the mechanical force provided by the valve stem, and the ball wedge is pressed to the seat, so that the sealing of the valve is not affected by the change of the pressure difference of the pipeline, and the sealing performance is reliably guaranteed under various working conditions.

6. Self-cleaning structure of sealing surface. When the ball tilts away from the seat, the fluid in the pipeline passes 360° evenly along the sealing surface of the ball, which not only eliminates the local erosion of the high-speed fluid on the seat, but also washes away the accumulation on the sealing surface to achieve the purpose of self-cleaning.

FAQ

1. What is 2PC BSLL valve?

The 2PC BSLL valve is a ball valve with a two-piece body design and bottom entry stem. It is commonly used for on/off control of liquids and gases in industrial applications.

2. What are the main features of ball valves?

Key features of ball valves include a spherical closing element that allows for quick and easy closing with minimal pressure drop.

3. What are the different types of ball valves?

There are many different types of ball valves, including floating ball valves, trunnion mounted ball valves and multi-port ball valves, each with its own unique design and application.

4. What materials are stainless steel ball valves usually made of?

Stainless steel ball valves are usually made of high-quality stainless steel materials, such as 316 stainless steel, which has excellent corrosion resistance and durability.

5. What are the main advantages of using stainless steel ball valves?

Some of the key advantages of using stainless steel ball valves include their corrosion resistance, durability, and ability to handle high pressures and temperatures.

6. What are the common applications of stainless steel ball valves?

Stainless steel ball valves are commonly used in a wide range of industrial applications, including the oil and gas, chemical processing, water treatment, and food and beverage industries.

7. How do I choose the right ball valve for my application?

When selecting a ball valve for your application, it is important to consider factors such as pressure rating, temperature range, material compatibility, and flow requirements.

8. What are the key considerations when installing a ball valve?

When installing a ball valve, it is important to ensure proper alignment, tight sealing, and proper support to prevent any potential leaks or failures.

9. What maintenance does a ball valve usually require?

Routine maintenance of ball valves may include lubrication, inspection for wear and corrosion, and occasional repair or replacement of seals and components.

10. Where can I buy 2PC BSLL, ball valves and stainless steel ball valves?

2PC BSLL, Ball Valves and Stainless Steel Ball Valves are available online and offline from various industrial suppliers, distributors and manufacturers.