PRODUCT PARAMETERS

| Product Name | Pipe reducer |

| Size | 1/2"-24" seamless, 26"-110" welded |

| Standard | ANSI B16.9, EN10253-2, DIN2616, GOST17378, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

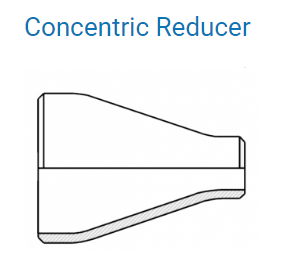

| Type | Concentric or eccentric |

| Process | seamless or welded with seam |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

APPLICATIONS OF STEEL PIPE REDUCER

The usage of a steel reducer is carried out in the chemical factories and power plants. It makes the piping system reliable and compact. It safeguards the piping system from any kind of adverse impact or thermal deformation. When it is on the pressure circle, it prevents from any type of leakage and is easy to install. The nickel or chrome coated reducers extends the product life, useful for high vapor lines, and prevents corrosion.

REDUCER TYPES

Concentric reducers are widely used while eccentric reducers are applied to maintain the top and bottom pipe level. Eccentric Reducers also avoids trapping of air inside the pipe, and Concentric Reducer removes noise pollution.

MANUFACTURING PROCESS OF STEEL PIPE REDUCER

There are versatile manufacturing processes for the reducers. These are made of welded pipes with the required filling material. However, EFW and ERW pipes cannot use the reducer. To manufacture forged parts, different kinds of methods are used including cold and hot forming processes.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

INSPECTION

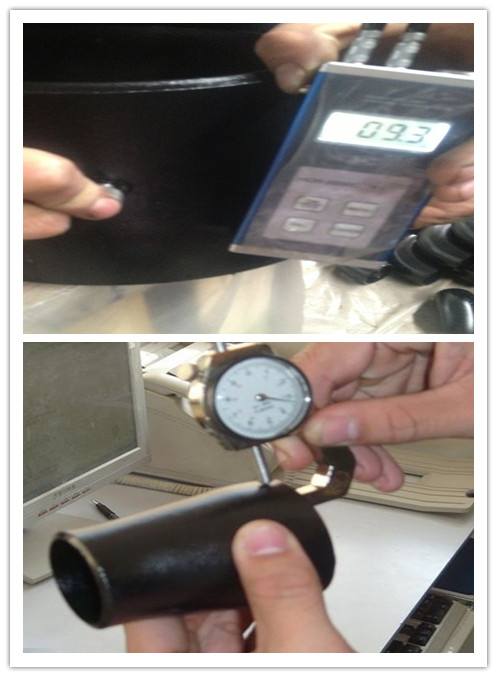

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. MT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate.

PACKAGING& SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

Heat treatment

1. Keep sample raw material to trace. 2. Arrange heat treatment as per standard strictly.

Marking

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

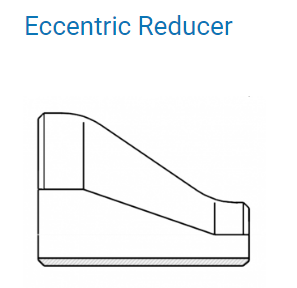

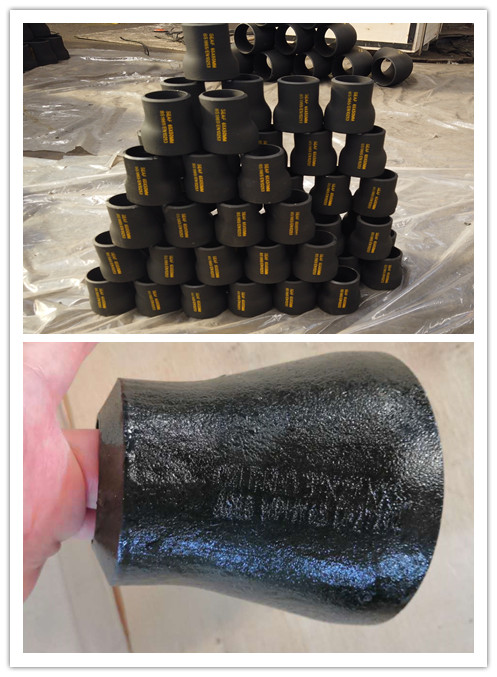

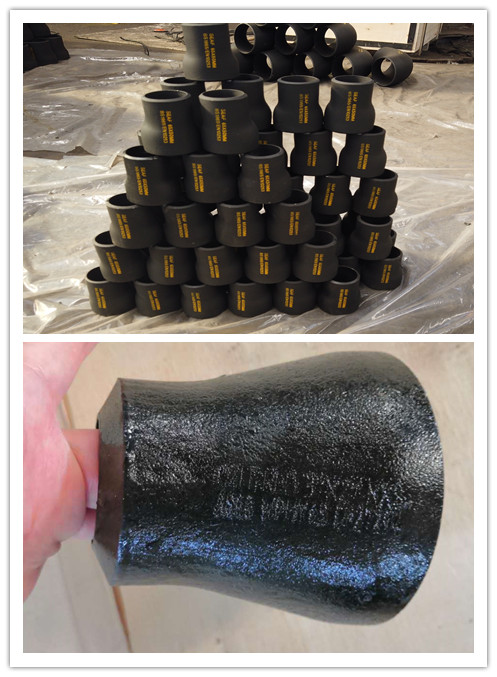

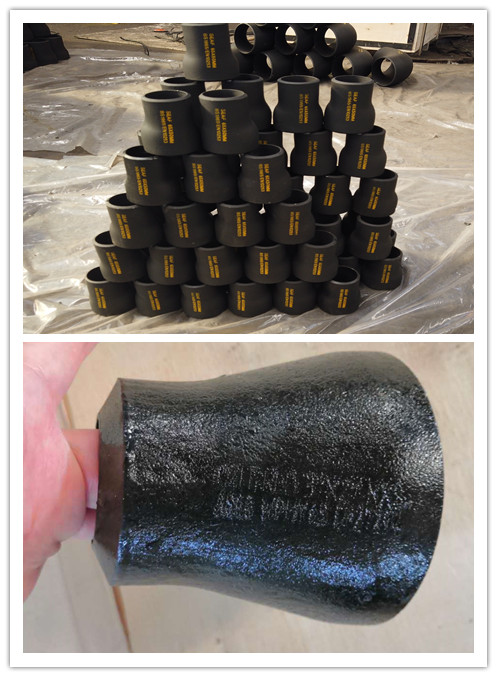

Detailed photos 1. Bevel end as per ANSI B16.25. 2. Sand blast first, then Perfect painting work. Also can be varnished 3. Without lamination and cracks 4. Without any weld repairs

Detailed photos 1. Bevel end as per ANSI B16.25. 2. Sand blast first, then Perfect painting work. Also can be varnished 3. Without lamination and cracks 4. Without any weld repairs

Inspection 1. Dimension measurements, all within standard tolerance. 2. Thickness tolerance:+/-12.5% , or on your request 3. PMI 4. MT, UT,X-ray test 5. Accept Third party inspection 6. Supply MTC, EN10204 3.1/3.2 certificate.

Inspection 1. Dimension measurements, all within standard tolerance. 2. Thickness tolerance:+/-12.5% , or on your request 3. PMI 4. MT, UT,X-ray test 5. Accept Third party inspection 6. Supply MTC, EN10204 3.1/3.2 certificate.

Packaging & Shipping 1. Packed by plywood case or plywood pallet as per ISPM15 2. we will put packing list on each package 3. we will put shipping markings on each package. Markings words are on your request. 4. All wood package materials are fumigation free

Packaging & Shipping 1. Packed by plywood case or plywood pallet as per ISPM15 2. we will put packing list on each package 3. we will put shipping markings on each package. Markings words are on your request. 4. All wood package materials are fumigation free

-

90 degree elbow tee reducer carbon steel Butt w...

-

Stainless Steel A403 WP316 Butt Weld Pipe Fitti...

-

ANSI B16.9 butt weld Pipe Fitting carbon steel ...

-

A234WPB ANSI B16.9 Pipe Fitting Elbow Alloy Ste...

-

Asme b16.9 schedule 80 steel pipe fittings tee ...

-

A234 WP22 WP11 WP5 WP91 WP9 Alloy Steel Elbow