PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless, 6"-110" welded with seam |

| Standard | ANSI B16.9, EN10253-4, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75,non-standard, etc. |

| Wall thickness | SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS ,customized and etc. |

| Degree | 30° 45° 60° 90° 180°,customized , etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D or customized |

| End | Bevel end/BE/buttweld |

| Surface | pickled, sand rolling, polished, mirror polishing and etc. |

| Material | Stainless steel: A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400, Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

WHITE STEEL PIPE ELBOW

White Steel elbow includes stainless steel elbow(ss elbow), super duplex stainless elbow and nickel alloy steel elbow.

ELBOW TYPE

Elbow could be ranged from direction angle, connection types, length and radius, material types, equal elbow or reducing elbow.

45/60/90/180 Degree Elbow

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

Classification by Material

Let us introduce some competitive materials we offer here:

Stainless steel elbow: Sus 304 sch10 elbow, 316L 304 Elbow 90 degree long radius elbow, 904L short elbow

Alloy steel elbow: Hastelloy C 276 Elbow, alloy 20 short elbow

Super duplex steel elbow:Uns31803 Duplex Stainless Steel 180 Degree Elbow

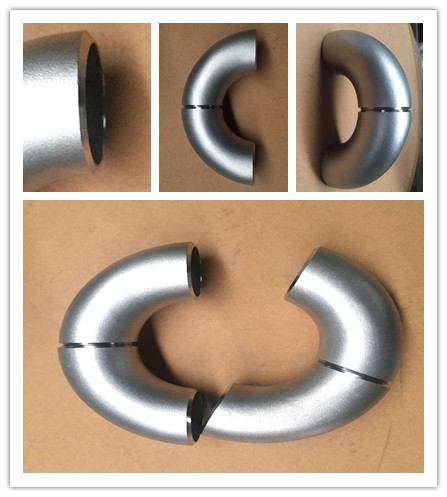

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE.

7. ASTM A262 practice E

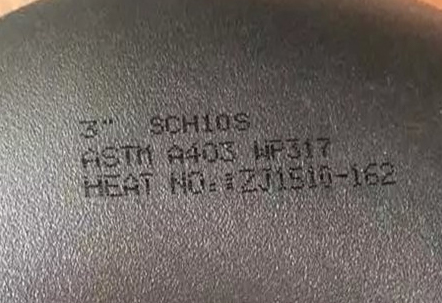

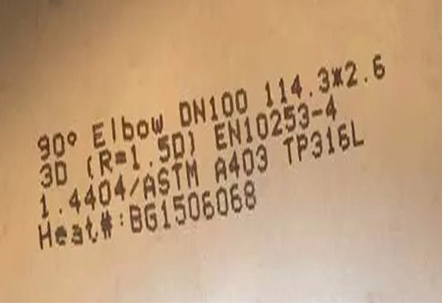

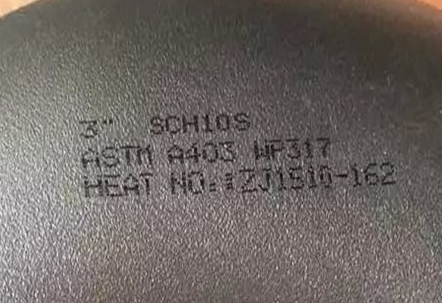

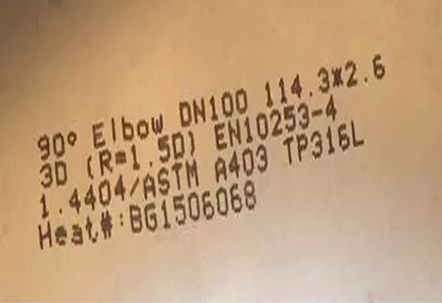

MARKING

Various marking work can be on your request. We accept mark your LOGO.

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15.

2. we will put packing list on each package.

3. we will put shipping markings on each package. Markings words are on your request.

4. All woodpackage materials are fumigation free.

FAQ

1. What is a stainless steel 45 degree elbow?

Stainless steel 45 degree elbow is a pipe fitting used to change the direction of water flow at a 45 degree angle. It is made of high-quality stainless steel material with excellent corrosion resistance and durability.

2. Can stainless steel 60-degree elbow withstand high temperatures?

Yes, stainless steel 60 degree elbows are designed to withstand high temperatures. They are often used in applications that require resistance to extreme heat, making them suitable for various industries such as oil and gas, chemicals and petrochemicals.

3. What is the use of stainless steel 90 degree elbow?

Stainless steel 90 degree elbow is used to change the direction of fluid flow by 90 degrees. It is commonly used in piping systems, food and beverage processing, the pharmaceutical industry, and other applications that require precise changes of direction.

4. Which industries commonly use stainless steel 180-degree elbows?

Stainless steel 180 degree elbows are widely used in various industries such as marine, automotive, HVAC (heating, ventilation and air conditioning) and industrial manufacturing. They are often used in piping systems to redirect flow or form U-shaped elbows.

5. What are the advantages of using stainless steel elbows?

Stainless steel elbows offer a variety of benefits, including superior corrosion resistance, high strength, and long-lasting performance. They are also easy to clean, making them ideal for applications requiring hygienic conditions, such as the food processing or pharmaceutical industries.

6. Are stainless steel elbows suitable for indoor and outdoor installation?

Yes, stainless steel elbows are versatile and suitable for both indoor and outdoor installations. Their corrosion-resistant properties allow them to withstand harsh environmental conditions, including exposure to moisture, moisture and extreme temperatures.

7. Can stainless steel elbows be welded?

Yes, stainless steel elbows can be welded using standard welding techniques. The welding process ensures a safe and leak-free connection between the elbow and the adjacent pipe or fitting, thereby enhancing the overall structural integrity of the system.

8. Are stainless steel elbows available in different sizes?

Yes, stainless steel elbows are available in a variety of sizes to accommodate a variety of pipe diameters and specifications. Common sizes include 1/2", 3/4", 1", 1.5", 2" and larger options ensuring compatibility with different pipes or duct systems.

9. Do stainless steel elbows require regular maintenance?

Stainless steel elbows are known for their low maintenance requirements. However, occasional cleaning may be necessary to remove dirt, debris, or stains that may affect the appearance or performance of the elbow. Routine inspections are also recommended to identify any signs of damage or wear.

10. Can stainless steel elbows be used in high pressure applications?

Yes, stainless steel elbows are often used in high pressure applications due to their excellent strength and corrosion resistance. However, it is important to select the appropriate grade and wall thickness of stainless steel elbow that can withstand the specific pressure requirements of the system.

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

Elbow could be ranged from direction angle, connection types, length and radius, material types.

Classified by Direction Angle

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

Classification by Material

According to the valve body material, it has stainless steel, carbon steel and alloy steel elbow.

Detailed photos

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients.

Inspection

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE.

7. ASTM A262 practice E

Marking

Various marking work can be on your request. We accept mark your LOGO.

Packaging & Shipping

1. Packed by plywood case or plywood pallet as per ISPM15.

2. we will put packing list on each package.

3. we will put shipping markings on each package. Markings words are on your request.

4. All woodpackage materials are fumigation free.