When it comes to industrial piping systems, the choice of forged couplings plays a crucial role in ensuring the efficiency and safety of the overall operation. Among the various options available, Forged Steel Half Couplings and Forged Steel Full Couplings are two commonly used components that serve distinct purposes in piping systems.

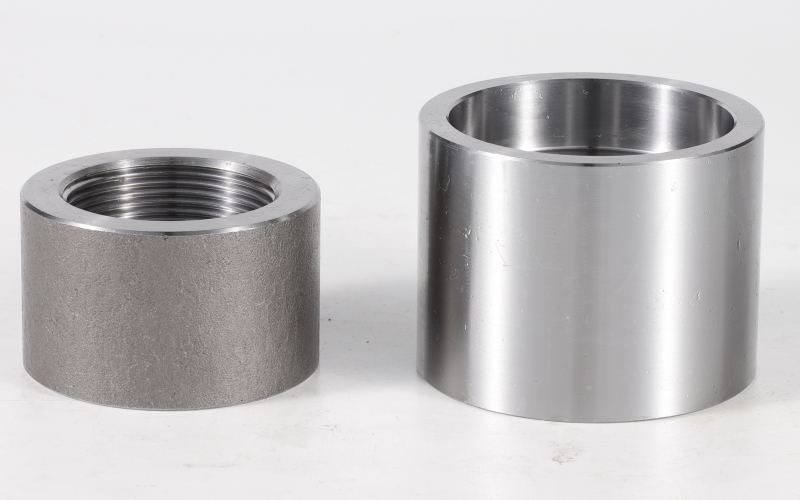

Forged Steel Half Coupling, as the name suggests, is a coupling that only covers half of the pipe’s circumference. It is designed to be welded onto the pipe, providing a connection point for another pipe or a fitting. This type of coupling is often used in applications where space is limited, or when the pipe needs to be joined to a different type of fitting.

On the other hand, Forged Steel Full Coupling covers the entire circumference of the pipe and is used to connect two pipes or fittings of the same size. It provides a complete and secure joint, ensuring the seamless flow of fluids or gases through the piping system. Full couplings are commonly used in straight runs of piping where a complete joint is required.

C.Z.IT DEVELOPMENT CO., LTD is a leading provider of high-quality Forged Steel Half Couplings and Forged Steel Full Couplings, offering a wide range of options to meet the diverse needs of industrial applications. With a commitment to precision engineering and durability, the company’s forged couplings are designed to withstand high pressure, temperature variations, and corrosive environments, ensuring long-term reliability and performance.

In conclusion, understanding the difference between Forged Steel Half Coupling and Forged Steel Full Coupling is essential for selecting the right component for a specific piping application. Whether it’s accommodating space constraints with a half coupling or creating a complete joint with a full coupling, C.Z.IT DEVELOPMENT CO., LTD provides the expertise and quality products to meet the demands of industrial piping systems.

Post time: Aug-08-2024