What is a stub end and why should it be used? Stub ends are buttweld fittings that can be used (in combination with a lap joint flange) alternatively to welding neck flanges to make flanged connections. The use of stub ends has two advantages: it can reduce the total cost of flanged joints for piping systems in high material grades (as the lap joint flange does not need to be of the same material of the pipe and the stub end but can be a lower grade); it speeds up the installation process, as the lap joint flange can be rotated to facilitate the alignment of the bolt holes. Stub ends are available in short and long pattern (ASA and MSS stub ends), in sizes up to 80 inches.

STUB END TYPES

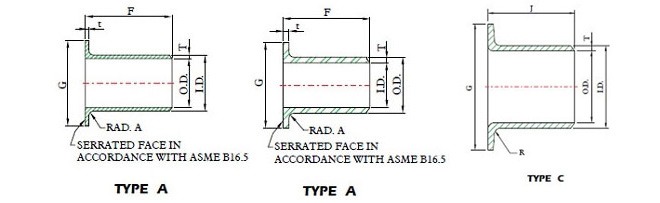

Stub ends are available in three different types, named “Type A”, “Type B” and “Type C”:

- The first type (A) is manufactured and machined to match standard lap joint backing flange (the two products have to be used in combination). The mating surfaces have an identical profile to permit a smooth loading of the flare face

- Stub ends type B are have to be used with standard slip-on flanges

- Type C stub ends can be used either with lap joint or slip-on flanges and are manufactured from pipes

SHORT/LONG PATTERN STUB ENDS (ASA/MSS)

Stub ends are available in two different patterns:

- the short pattern, called MSS-A stub ends

- the long pattern, called ASA-A stub ends (or ANSI length stub end)

Post time: Mar-23-2021