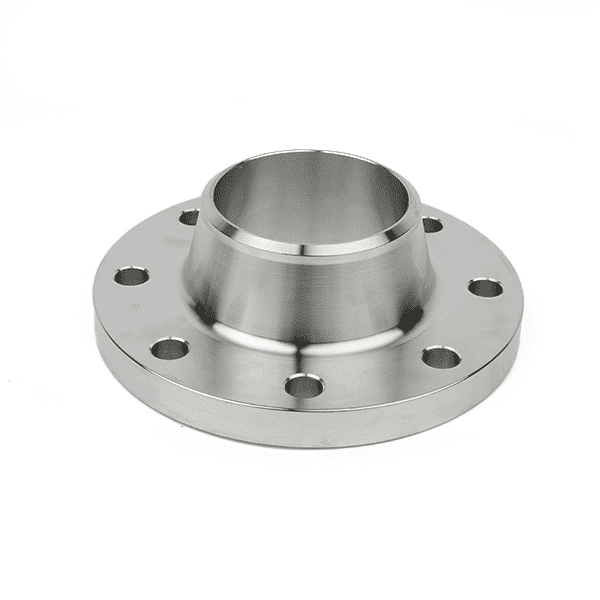

High Quality Forged Din2573 Flange - Forged Weld Neck Flange – C. Z. IT Detail:

Specification

| Product Name | weld neck flange |

| Size | 1/2″-110″ |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

Production process

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

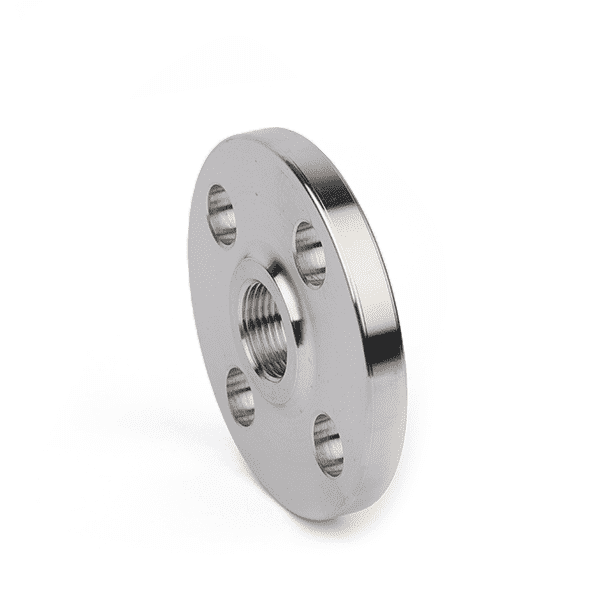

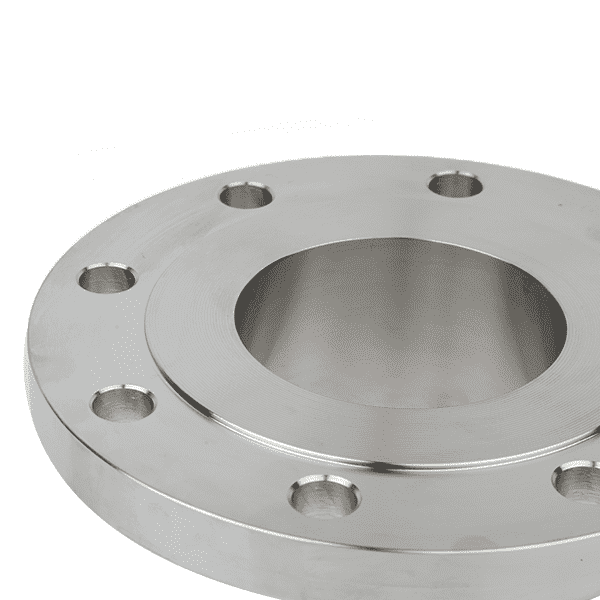

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for High Quality Forged Din2573 Flange - Forged Weld Neck Flange – C. Z. IT, The product will supply to all over the world, such as: California, Mauritania, Mongolia, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!