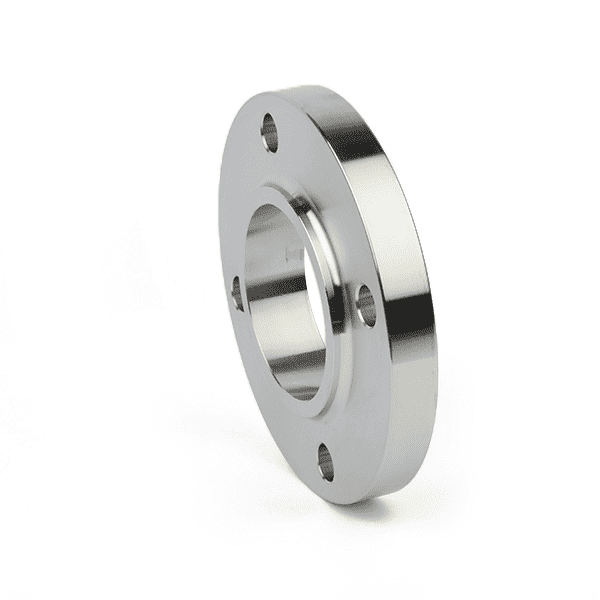

Good Wholesale Vendors 1.5 Weld Neck Flange - Forged Slip On Flange – C. Z. IT Detail:

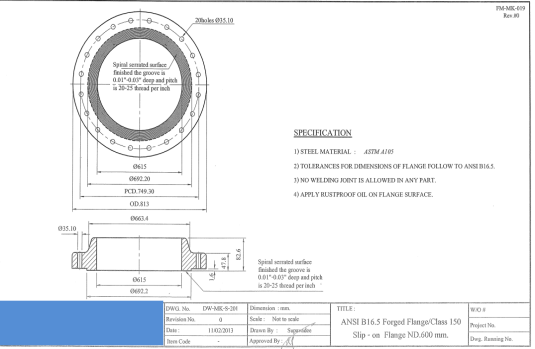

Specification

| Porduct Name | Slip on flange |

| Size | 1/2″-110″ |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry, aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

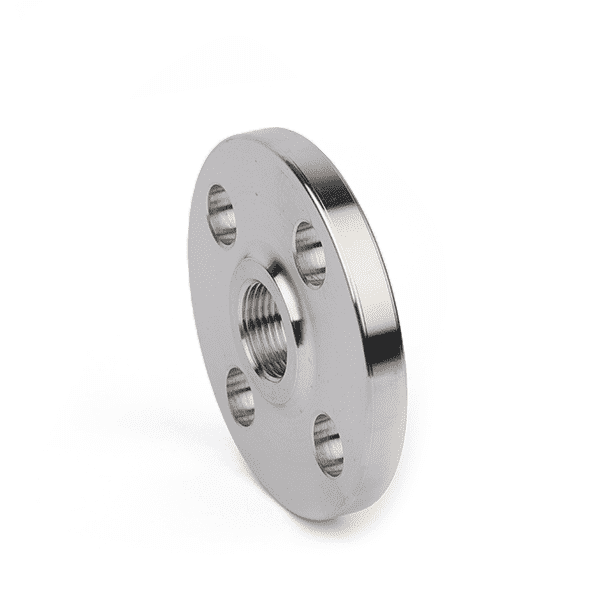

Products detail show

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2. Slip on with hub, flat welding. Also can offer slip on without hub.

3. CNC fine finished

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

Marking and packing

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

Inspection

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

Cooperation Case

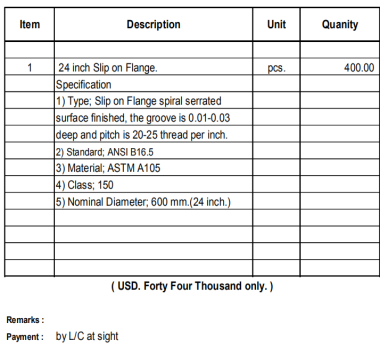

A project from Thailand, 24” slip on flanges are used in Municipal Engineering.

Product detail pictures:

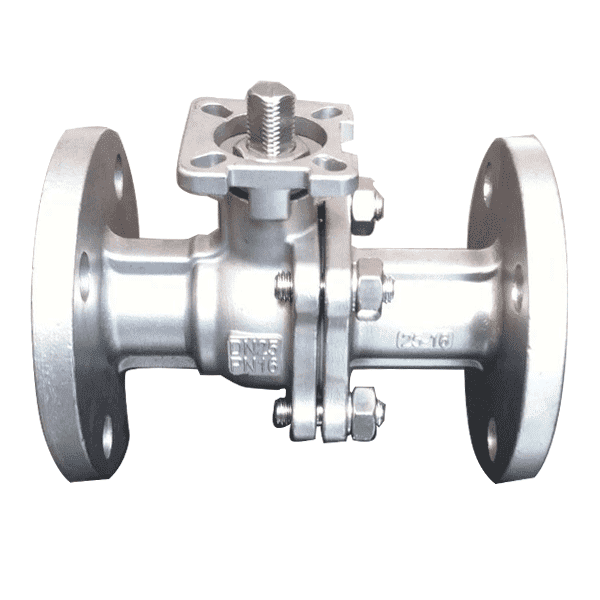

Related Product Guide:

What are duplex stainless steel applications?

Our commission is to serve our users and clients with best quality and competitive portable digital products for Good Wholesale Vendors 1.5 Weld Neck Flange - Forged Slip On Flange – C. Z. IT, The product will supply to all over the world, such as: Russia, South Korea, Rotterdam, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Excellent quality Boiler Pipe - Black Steel Pi...

-

Factory Supply Erw Steei Pipe - Black Steel Pi...

-

Reasonable price for Forged Ansi B16.5 Flange -...

-

Manufactur standard Forged Coupling - Forged P...

-

OEM Factory for Sw Titanium Flange - Forged Th...

-

100% Original Factory Check Valve Male/Male - ...