Gate valves are used to shut off the flow of liquids rather than for flow regulation. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance.The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow.

Design Features

- Outside Screw and Yoke(OS&Y)

- Two Piece self aligning packing gland

- Bolted bonnet with spiral-wound gasket

- Integral backseat

Specifications

- Basic Design: API 602, ANSI B16.34

- End to End: DHV Standard

- Test & Inspection: API-598

- Screwed Ends (NPT) to ANSI/ASME B1.20.1

- Socket weld Ends to ASME B16.11

- Butt weld Ends to ASME B16.25

- End Flange: ANSI B16.5

Optional Features

- Cast Steel, Alloy Steel, Stainless Steel

- Full Port or Regular Port

- Extended Stem or Below Seal

- Welded Bonnet or Pressure Seal Bonnet

- Locking Device upon request

- Manufacturing to NACE MR0175 upon request

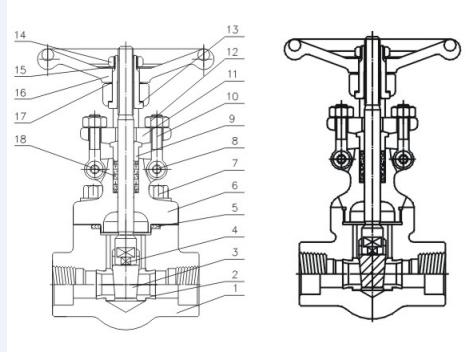

Products Drawing

Application Standards

1. Design and manufacture conform to API 602,BS5352,ANSI B 16.34

2.Connection ends confrom to :

1) Socket weld dimension conform to ANSI B 16.11 ,JB/T 1751

2)Screw ends dimension conform to ANSI B 1.20.1,JB/T 7306

3)Butt-Welded conform to ANSI B16.25,JB/T12224

4)Flanged ends conformto ANSI B 16.5,JB79

3.Test and inspection conform to :

1)API 598,GB/T 13927,JB/T9092

4.Structure features:

Bolted bonnet,outside screw and yoke

Welded bonnet,outside scres and yoke

5.MAterials conform to ANSI/ASTM

6.main Materials:

A105,LF2,F5,F11,F22,304(L),316(L),F347,F321,F51,Monel,20Alloy

Carbon steel Temperature-Pressure rate

CL150-285 P.S.I@ 100°F

CL300-740 P.S.I@ 100°F

CL600-1480 P.S.I@ 100°F

CL800-1975 P.S.I@ 100°F

CL1500-3705 P.S.I@ 100°F

Main Part Materials List

| NO | Part Name | A105/F6a | A105/F6a HFS | LF2/304 | F11/F6AHF | F304(L) | F316(L) | F51 |

| 1 | Body | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F51 |

| 2 | Seat | 410 | 410HF | 304 | 410HF | 304(L) | 316(L) | F51 |

| 3 | Wedge | F6a | F6a | F304 | F6aHF | F304(L) | F306(L) | F51 |

| 4 | Stem | 410 | 410 | 304 | 410 | 304(L) | 316(L) | F51 |

| 5 | Gasket | 304+Flexible Graphite | 304+Flexible Graphite | 304+Flexible Graphite | 304+Flexible Graphite | 304+Flexible Graphite | 316+Flexible Graphite | 316+Flexible Graphite |

| 6 | Bonnet | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F51 |

| 7 | Bolt | B7 | b7 | L7 | B16 | B8(M) | B8(M) | B8(M) |

| 8 | Pin | 410 | 410 | 410 | 410 | 304 | 304 | 304 |

| 9 | Gland | 410 | 410 | 304 | 410 | 304 | 316 | F51 |

| 10 | Gland eyebolt | B7 | B7 | L7 | B16 | B8M | B8M | B8M |

| 11 | Gland Flange | A105 | A105 | LF2 | F11 | F304 | F304 | F304 |

| 12 | Hex nut | 2H | 2H | 2H | 2H | 8M | 8M | 8M |

| 13 | Stem nut | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 14 | Locking nut | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| 15 | Nameplate | AL | AL | AL | AL | AL | AL | AL |

| 16 | Handwheel | A197 | A197 | A197 | A197 | A197 | A197 | A197 |

| 17 | LubricatingGasket | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 18 | Packing | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite |