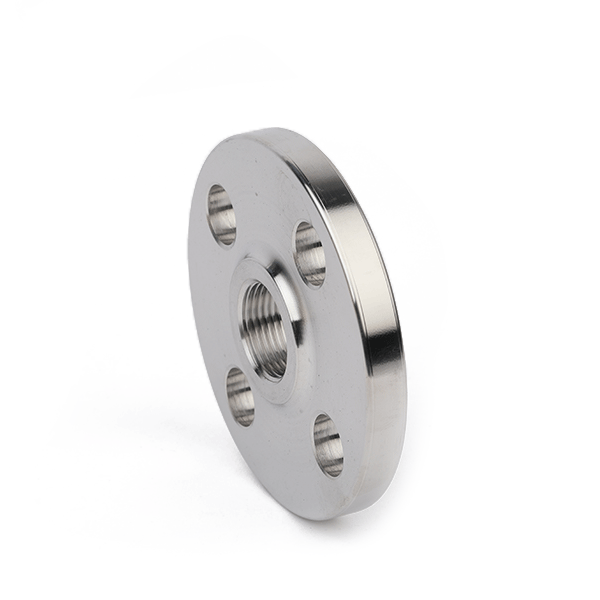

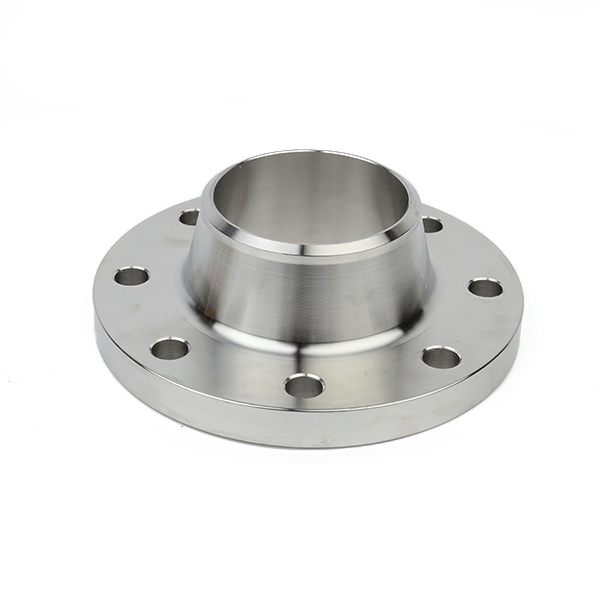

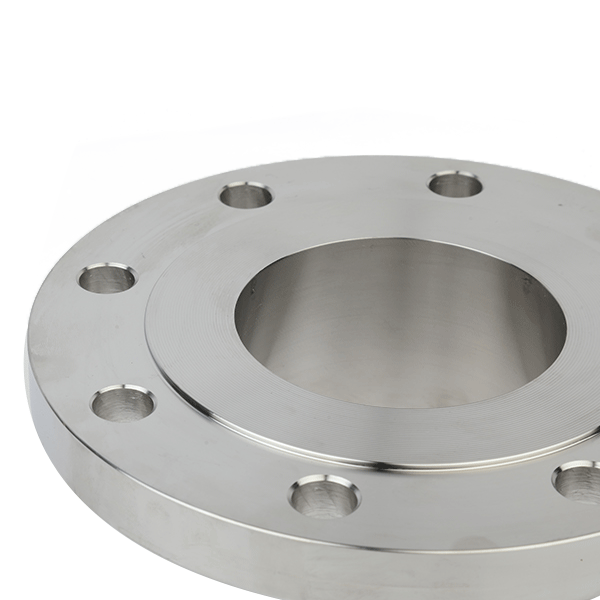

Factory For Blind Flanges - Forged Weld Neck Flange – C. Z. IT Detail:

Specification

| Product Name | weld neck flange |

| Size | 1/2″-110″ |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

Production process

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Factory For Blind Flanges - Forged Weld Neck Flange – C. Z. IT, The product will supply to all over the world, such as: Bandung, Namibia, Angola, More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,