SPECIFICATION

| Product Name | Blind flange |

| Size | 1/2"-250" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

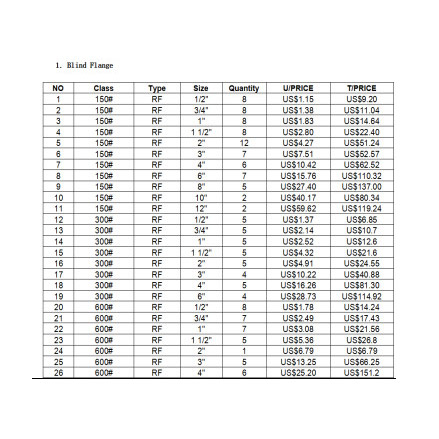

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2.Seal face

smooth face, waterlines, serrated finished

3.CNC fine finished

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

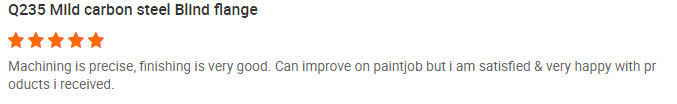

COOPERATION CASE

This order is for Malaysia stockist. After receiving the goods, client gave us FIVE STAR favourable comments. While as his advising, we already improved our painting job.

FAQ

1. What is A105 carbon steel forged blind flange?

A105 Carbon Steel Forged Blind Flange is a flange made from carbon steel grade ASTM A105. It is used to close the end of a pipe or valve to prevent fluid flow. This flange has no holes and is therefore blind flange or impenetrable.

2. What are the characteristics of A105 carbon steel forged blind plates?

A105 carbon steel forged blind flange has the characteristics of high tensile strength, good corrosion resistance and high dimensional accuracy. It can withstand high pressure and high temperature conditions without deformation.

3. What are the uses of A105 carbon steel forged blind plates?

A105 carbon steel forged blind plates are commonly used in various industries such as oil and gas, petrochemicals, refineries, power plants and water treatment. It is suitable for applications where pipes require closed ends.

4. What are the advantages of using A105 carbon steel to forge blind plates?

Some of the advantages of using A105 carbon steel forged blind flanges are their cost-effectiveness, durability and ease of installation. It provides a safe, leak-free closure for pipes or valves.

5. What sizes are available for A105 carbon steel forged blind flanges?

A105 carbon steel forged blind flanges are available in a variety of sizes, ranging from 1/2" to 60". Size selection depends on the pipe or valve that needs to be closed.

6. What are the pressure rating options for A105 carbon steel forged blind flanges?

Pressure rating options for A105 carbon steel forged blind flanges range from Class 150 to Class 2500. The choice of pressure rating depends on the specific application and the pressure conditions it needs to withstand.

7. Can A105 carbon steel forged blind flange be used with different pipe materials?

Yes, A105 carbon steel forged blind flanges can be used with different pipe materials, such as carbon steel, stainless steel, alloy steel and PVC pipes. It is compatible with a variety of piping systems.

8. Does A105 carbon steel forged blind flange require special coating?

A105 carbon steel forged blind flanges do not require any special coating in normal applications. However, for corrosive environments or specific requirements, it can be coated with materials such as epoxy or galvanized coatings.

9. What is the testing procedure for A105 carbon steel forged blind flange?

A105 carbon steel forged blind plates undergo various tests such as hydrostatic testing, ultrasonic testing, radiographic testing, visual inspection, dimensional inspection, etc. to ensure their quality and performance.

10. Where can I buy A105 carbon steel forged blind flange?

A105 carbon steel forged blind flanges are available from various authorized dealers, manufacturers and suppliers. Online industrial supply stores or local hardware stores that specialize in plumbing products may also have them in stock.