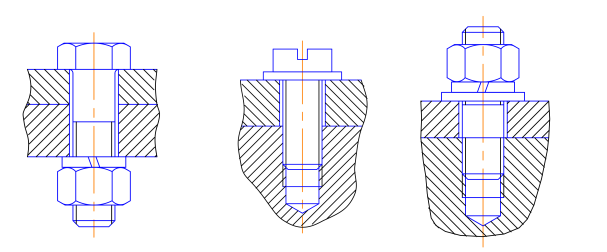

Different type bolt

The difference between bolts and screws lies in two aspects: one is the shape, the stud part of the bolt is strictly required to be cylindrical, used to install the nut, but the stud part of the screw is sometimes conical or even with a tip; the other is Using the function, the screw is screwed into the target material instead of the nut. In many occasions, the bolts also work individually, and are directly screwed into the pre-drilled threaded hole, without the need for a nut to cooperate with it. At this time, the bolt is classified as a screw in terms of function.

The shape and purpose of the bolt head are divided into hexagonal head bolts, square head bolts, half-round head bolts, countersunk head bolts, bolts with holes, T-head bolts, hook head (foundation) bolts and so on.

The thread of the column can be divided into coarse thread, fine thread and inch thread, so it is called fine bolt and inch bolt.

Production Process

First, the first punch moves to prepare the wire for forming, and then the second punch moves to forge the wire again and shape the finished product. In the cold heading process, the fixed die (compression die) and the stamping (flattening) die (punching)

The number of heads) is not the same. Some complex screws may require multiple punches to form together, which requires multi-station equipment to make the screw forming.After the movement of the punch, the head of the screw has been completed, but the part of the screw shaft has not been threaded.The method of forming the screw thread is thread rolling. Thread rolling is the use of two relatively rotating thread rolling dies(rubbing plates) with threaded teeth to squeeze a cylindrical blank formed by amulti-station or heading machine in the middle.

After heading and rubbing the teeth, the entire screw has been produced. Of course, in order to make the appearance of the screw brighter and better, the surface treatment process is usually done. Such as cleaning and passivation of stainless steel screws,electroplating on the surface of carbon steel screws, etc. Made into various colors of screw fasteners.