PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless, 6"-110" welded with seam |

| Standard | ANSI B16.9, EN10253-4, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75,non-standard, etc. |

| Wall thickness | SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS ,customized and etc. |

| Degree | 30° 45° 60° 90° 180°,customized , etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D or customized |

| End | Bevel end/BE/buttweld |

| Surface | pickled, sand rolling, polished, mirror polishing and etc. |

| Material | Stainless steel: A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400, Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

WHITE STEEL PIPE ELBOW

White Steel elbow includes stainless steel elbow(ss elbow), super duplex stainless elbow and nickel alloy steel elbow.

ELBOW TYPE

Elbow could be ranged from direction angle, connection types, length and radius, material types, equal elbow or reducing elbow.

45/60/90/180 Degree Elbow

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

Classification by Material

Let us introduce some competitive materials we offer here:

Stainless steel elbow: Sus 304 sch10 elbow, 316L 304 Elbow 90 degree long radius elbow, 904L short elbow

Alloy steel elbow: Hastelloy C 276 Elbow, alloy 20 short elbow

Super duplex steel elbow:Uns31803 Duplex Stainless Steel 180 Degree Elbow

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE.

7. ASTM A262 practice E

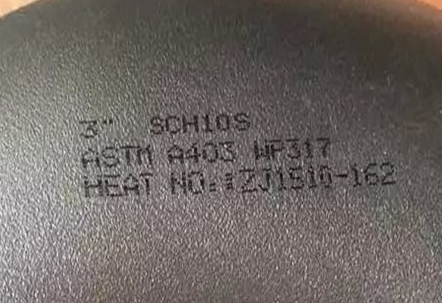

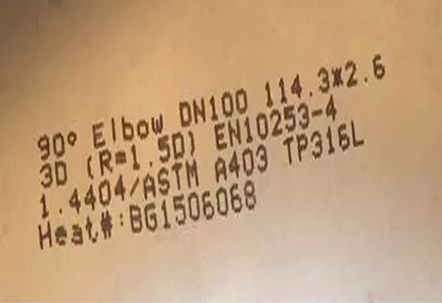

MARKING

Various marking work can be on your request. We accept mark your LOGO.

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15.

2. we will put packing list on each package.

3. we will put shipping markings on each package. Markings words are on your request.

4. All woodpackage materials are fumigation free.

FAQ

1. What is ANSI B16.9 stainless steel 45 degree butt welding elbow?

- ANSI B16.9 Stainless Steel 45 Degree Butt Weld Elbow is a pipe fitting used to change the direction of flow in a piping system by 45 degrees.

2. What materials are used to manufacture ANSI B16.9 stainless steel 45-degree butt welding elbows?

- These elbows are made of high-quality stainless steel, such as ASTM A403 WP304/304L or WP316/316L, for excellent corrosion resistance and durability.

3. What are the advantages of using ANSI B16.9 stainless steel 45-degree butt welded pipe elbow?

- These elbows offer smooth flow, reduced pressure drop and excellent corrosion resistance, making them suitable for a variety of industrial applications.

4. What is the pressure level of ANSI B16.9 stainless steel 45-degree butt weld elbow?

- The pressure rating of these elbows depends on the pipe size and material used. Common pressure ratings include 150 pounds, 300 pounds, and 600 pounds.

5. Are ANSI B16.9 stainless steel 45-degree butt weld elbows suitable for high temperature applications?

- Yes, these elbows are designed to withstand high temperature environments and are ideal for applications such as the petrochemical, oil and gas, and power generation industries.

6. What sizes are available for ANSI B16.9 stainless steel 45-degree butt weld elbow?

- These elbows are available in various sizes ranging from 1/2 inch to 48 inches to accommodate different pipe diameters and system requirements.

7. Can ANSI B16.9 stainless steel 45 degree butt weld elbow be used in horizontal and vertical applications?

- Yes, these elbows can be used in both horizontal and vertical ductwork as long as they meet the required specifications and provide appropriate support.

8. Can ANSI B16.9 stainless steel 45-degree butt weld pipe elbow be interchanged with other pipe fittings?

- Yes, these elbows are designed to be compatible with other ANSI B16.9 standard pipe fittings and can be easily integrated into existing piping systems.

9. How to install ANSI B16.9 stainless steel 45-degree butt welding elbow?

- These elbows are usually welded to the pipe using the butt welding technique. Professional installation is recommended to ensure a secure connection and no leaks.

10. Is it possible to order customized ANSI B16.9 stainless steel 45-degree butt welding elbow?

- Yes, some manufacturers offer custom manufacturing services to meet specific project requirements. For more information about custom orders, please contact the supplier or manufacturer.

-

ANSI B16.9 Carbon Steel 45 Degree Welding Bend

-

Stainless Steel A403 WP316 Butt Weld Pipe Fitti...

-

ASTM B 16.9 Pipe Fitting Carbon Steel Butt Weld...

-

DN50 50A sch10 90 elbow pipe fitting LR seamles...

-

Stainless Steel Welding Pipe End pressure vesse...

-

3050mm API 5L X70 WPHY70 Welded pipe fitting elbow