PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless elbow(SMLS elbow), 26"-110" welded with seam. Biggest outside diameter can be 4000mm |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Degree | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 , 12crmov, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

PIPE FITTINGS

Butt welded pipe fittings includes steel pipe elbow, steel pipe tee, steel pipe reduer, steel pipe cap. All those butt welding pipe fittings, we can supply together, we have more 20 years production experiences.

If you are also interested other fittings, please click followed LINK to check details.

PIPE TEE PIPE REDUCER PIPE CAP PIPE BEND FORGED FITTINGS

BUTT WELDED PIPE ELBOW

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

For industrial pipe elbow, the connectin end type is butt weld, according to ANSI B16.25. Butt welded can described butt welding, buttweld, bevel end. BW

ELBOW TYPE

Elbow could be ranged from direction angle, connection types, length and radius, material types.

Classified by Direction Angle

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

For 90 degree elbow, also described 90d elbow, or 90 deg elbow.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

If radius more than 1.5D, always named bend. elbow bend pipe fittings. Such as 2d elbow, 2d bend, 3d elbow, 3d bend, etc.

Classification by Material

Carbon steel, also called mild steel or black steel. Such as ASTM A234 WPB

Looking for stainless steel elbows, please click this link to find more details: STAINLESS STEEL ELBOWS

Shape Type

Can be equal elbow or Reducing elbow

ELBOW SURFACE

Sand Blast

After hot forming, we arrange sand blast to make the surface to be clean and smooth.

After Sand blast, to avoid get rust, should do black painting or anti-rust oil, Hot dip galvanized (HDG) , epoxy, 3PE, vanished surface, etc. That is depend on customer's request.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO.

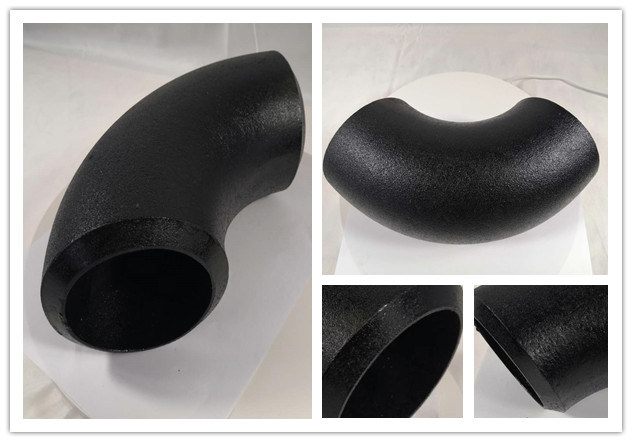

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished.

3. Without lamination and cracks.

4. Without any weld repairs.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. MT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate

PACKAGING& SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

FAQ

1. What is ANSI B16.9?

ANSI B16.9 refers to the American National Standards Institute (ANSI) standard for factory-made forged butt-weld pipe fittings. It specifies the dimensions, tolerances, materials and testing requirements for butt welded pipe fittings.

2. What are butt welded pipe fittings?

Butt weld fittings are pipe fittings that are welded to the ends of pipes or other fittings to form a strong, leak-proof joint. A butt weld connection is made by inserting the end of a pipe or fitting into the socket of another pipe or fitting and welding the joint.

3. What is a carbon steel 180 degree welding elbow?

Carbon steel 180 degree welded elbow is a pipe fitting used to change the direction of the pipe 180 degrees. It is available in long or short radius designs and is made from carbon steel material. Use a butt weld connection to connect an elbow to a pipe or other fitting.

4. What are the requirements for welded elbows in ANSI B16.9?

ANSI B16.9 specifies the dimensions, tolerances, materials, and testing requirements for welded elbows. It provides guidance on the manufacturing process, including outer diameter, wall thickness, center-to-end dimensions and radius of curvature for different sized elbows.

5. What are the advantages of using carbon steel for butt welded pipe fittings?

Carbon steel is widely used in butt welded pipe fittings due to its excellent strength, durability and corrosion resistance. It can withstand high pressure and high temperature environments and has a relatively high cost performance. Carbon steel fittings are suitable for a variety of applications in the oil and gas, petrochemical and power generation industries.

6. Can carbon steel 180-degree elbow be used in both high-pressure and low-pressure systems?

Yes, carbon steel 180 degree welded elbows can be used in both high and low pressure systems. However, the specific pressure rating of the elbow should be considered based on the application requirements. Accessories must be verified for compatibility with expected system pressures.

7. Is the carbon steel 180-degree welded elbow suitable for corrosive environments?

Yes, carbon steel fittings are generally suitable for use in corrosive environments. However, the type and concentration of corrosive media should be considered when selecting materials. In more corrosive environments, additional corrosion protection may be required, such as exterior coatings or linings.

8. Can carbon steel 180-degree elbows be used with pipes made of other materials?

Yes, carbon steel 180-degree welded elbows can be used with pipes made of stainless steel, alloy steel, non-ferrous metals and other materials. However, for long-term performance, compatibility between materials and potential galvanic corrosion effects should be considered.

9. What tests have been performed on ANSI B16.9 carbon steel 180 degree elbows?

ANSI B16.9 specifies various tests to ensure the quality and integrity of carbon steel 180 degree welded elbows. These tests may include dimensional inspection, visual inspection, ultrasonic inspection, tensile strength testing, impact testing and non-destructive testing (such as dye penetration or radiographic inspection).

10. Can carbon steel 180-degree elbows be modified or welded on site?

Carbon steel 180 degree elbows can be modified or welded in the field but should be done by qualified and experienced personnel in accordance with industry standards and procedures. It is recommended to consult the manufacturer or professional engineer for guidance to ensure the safety and performance of modified accessories.

-

3050mm API 5L X70 WPHY70 Welded pipe fitting elbow

-

carbon steel 45 degree bend 3d bw 12.7mm WT AP...

-

Pipe Fittings Stainless Steel White Steel Forge...

-

ASME B16.9 A234 SCH 40 STD Butt Welded carbon s...

-

A234WPB ANSI B16.9 Pipe Fitting Elbow Alloy Ste...

-

ASMEB 16.5 Stainless steel 304 316 904L butt we...