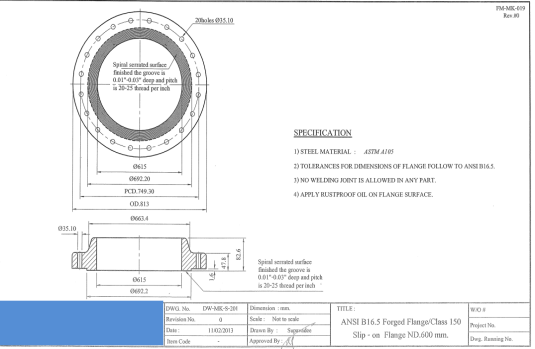

SPECIFICATION

| Porduct Name | Slip on flange |

| Size | 1/2"-110" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry, aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

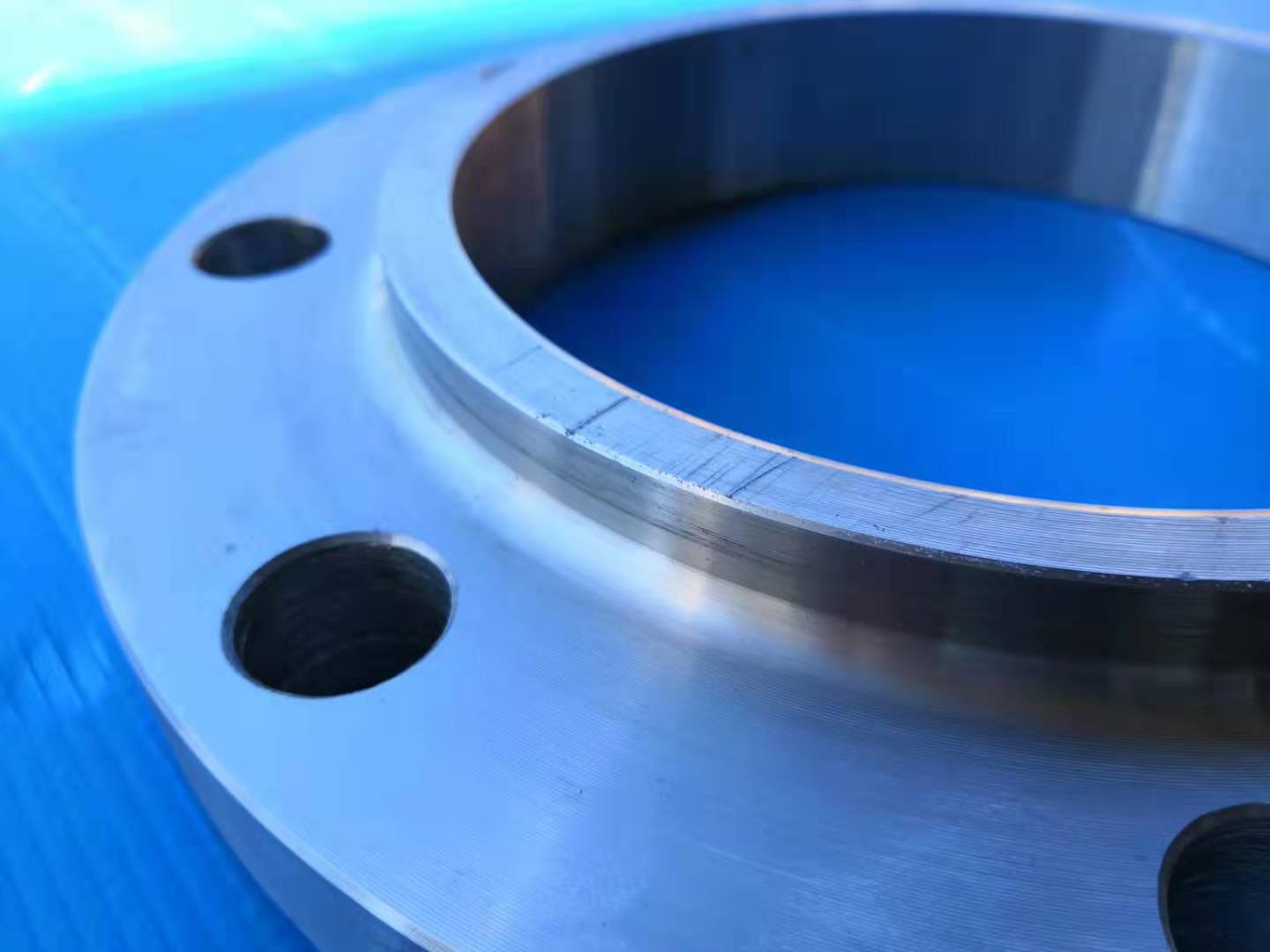

PRODUCTION DETAIL SHOW

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2. Slip on with hub, flat welding. Also can offer slip on without hub.

3. CNC fine finished

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

COOPERATION CASE

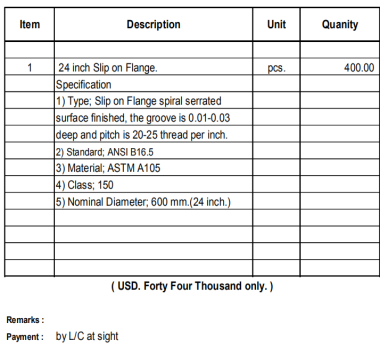

A project from Thailand, 24” slip on flanges are used in Municipal Engineering.

FAQ

1. What is ANSI B16.5 A105 black carbon steel sliding flange?

ANSI B16.5 A105 black carbon steel sliding sleeve flange is a flange made of black carbon steel and designed in accordance with ANSI B16.5 standards. It has a slip-on design that slides onto the pipe and is welded into place.

2. What are the dimensions of ANSI B16.5 A105 black carbon steel sliding flange?

ANSI B16.5 A105 black carbon steel slip-on flanges vary in size depending on the size of pipe they are to be installed on. It is available in sizes from 1/2" to 24" to accommodate different pipe specifications.

3. What are the applications of ANSI B16.5 A105 black carbon steel sliding flange?

ANSI B16.5 A105 black carbon steel slip-on flanges are commonly used in industries such as oil and gas, petrochemical, power plants and water treatment. Suitable for connecting pipes, valves, pumps and other equipment.

4. What is the pressure rating of ANSI B16.5 A105 black carbon steel sliding flange?

ANSI B16.5 A105 black carbon steel slip-on flanges are pressure rated depending on size and grade rating. It can handle different pressure levels from ANSI 150 to ANSI 2500.

5. Can ANSI B16.5 A105 black carbon steel slip-on flanges be used in high temperature applications?

Yes, ANSI B16.5 A105 black carbon steel slip-on flanges are available for high temperature applications. However, it is important to consider the maximum temperature limits specified by the manufacturer to ensure suitability.

6. What is the difference between ANSI B16.5 A105 black carbon steel flat welding flange and other types of flanges?

The main difference between the ANSI B16.5 A105 black carbon steel slip-on flange and other flanges is its slip-on design. Unlike welded or threaded flanges, it easily slides onto the pipe and is welded in place.

7. Are ANSI B16.5 A105 black carbon steel sliding flanges corrosion-resistant?

ANSI B16.5 A105 black carbon steel slip-on flanges are not inherently corrosion resistant. However, corrosion can be prevented by applying appropriate coatings or using corrosion-resistant materials.

8. Can ANSI B16.5 A105 black carbon steel flat weld flanges be used with pipes made of other materials?

Yes, ANSI B16.5 A105 black carbon steel slip-on flanges can be used with pipe made of other materials. However, it is critical to ensure compatibility between flange and pipe materials to prevent issues such as galvanic corrosion.

9. How should ANSI B16.5 A105 black carbon steel flat welding flange be installed?

The ANSI B16.5 A105 black carbon steel slip-on flange is installed by sliding it onto the pipe, aligning the bolt holes, and then welding it in place. Proper welding techniques and procedures should be followed to ensure a tight and leak-free connection.

10. Where can I buy ANSI B16.5 A105 black carbon steel sliding flange?

ANSI B16.5 A105 black carbon steel slip-on flanges are available from various authorized dealers, manufacturers and suppliers. It is recommended to choose a reliable source that provides high-quality products and has a good reputation in the industry.

-

stainless steel forged lap joint loose flange c...

-

Customized Non-Standard Tube Sheet Flange Stain...

-

AMSE B16.5 A105 forged carbon steel weld neck f...

-

Screw BSP DIN PN 10/16 carbon steel A105 flange...

-

DIN ANSI 150LB PN16 stainless steel 304 316 316...

-

ASME B16.48 CL150 CL300 Paddle spacer plank fla...